Technische Richtlinie (TR) – The German Schutzklasse standard edition 2008

The NIJ Standard 0101.06 is the latest standard for bulletproof vests, establishing minimum resistance requirements and testing methods for vests and ballistic plates. This standard applies exclusively to bulletproof vests and plates, and does not cover threats from edged blades or pointed instruments, which are addressed by NIJ Standard 0115.00.

NIJ 2005 was made in order to make sure that the material Zylon was never used in the manufacturing of .04 certified bulletproof vests. Zylon was a ballistic material that after some time lost its bulletproof durability, where several US police officers lost their lives with Zylon in their bulletproof vest.

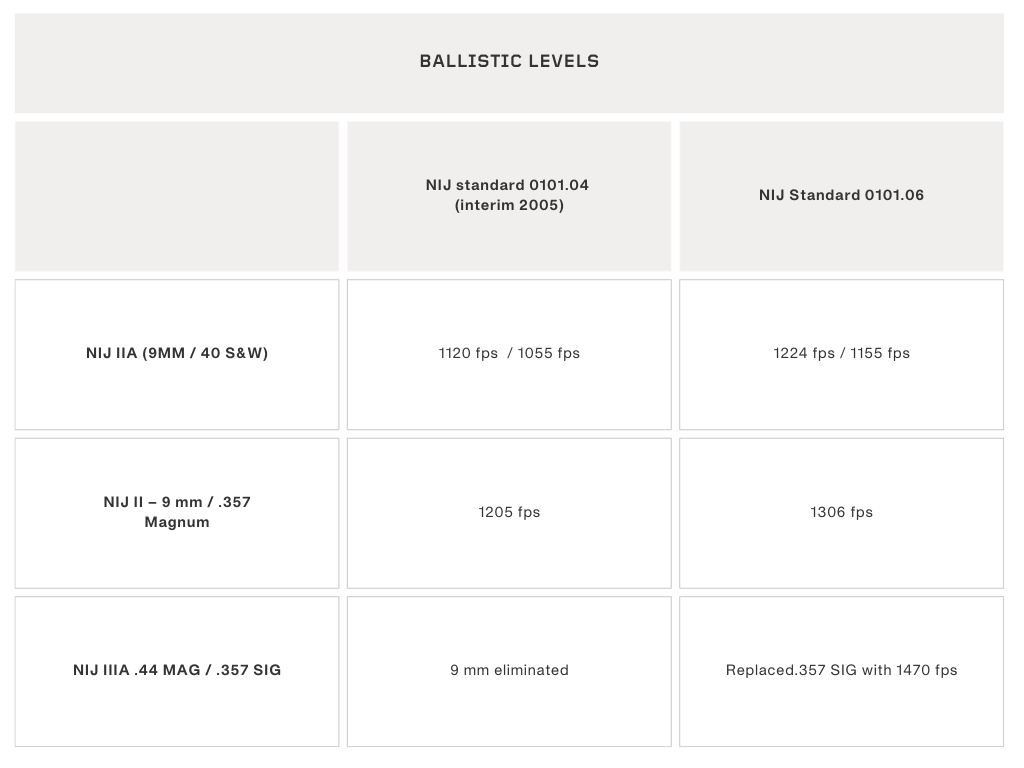

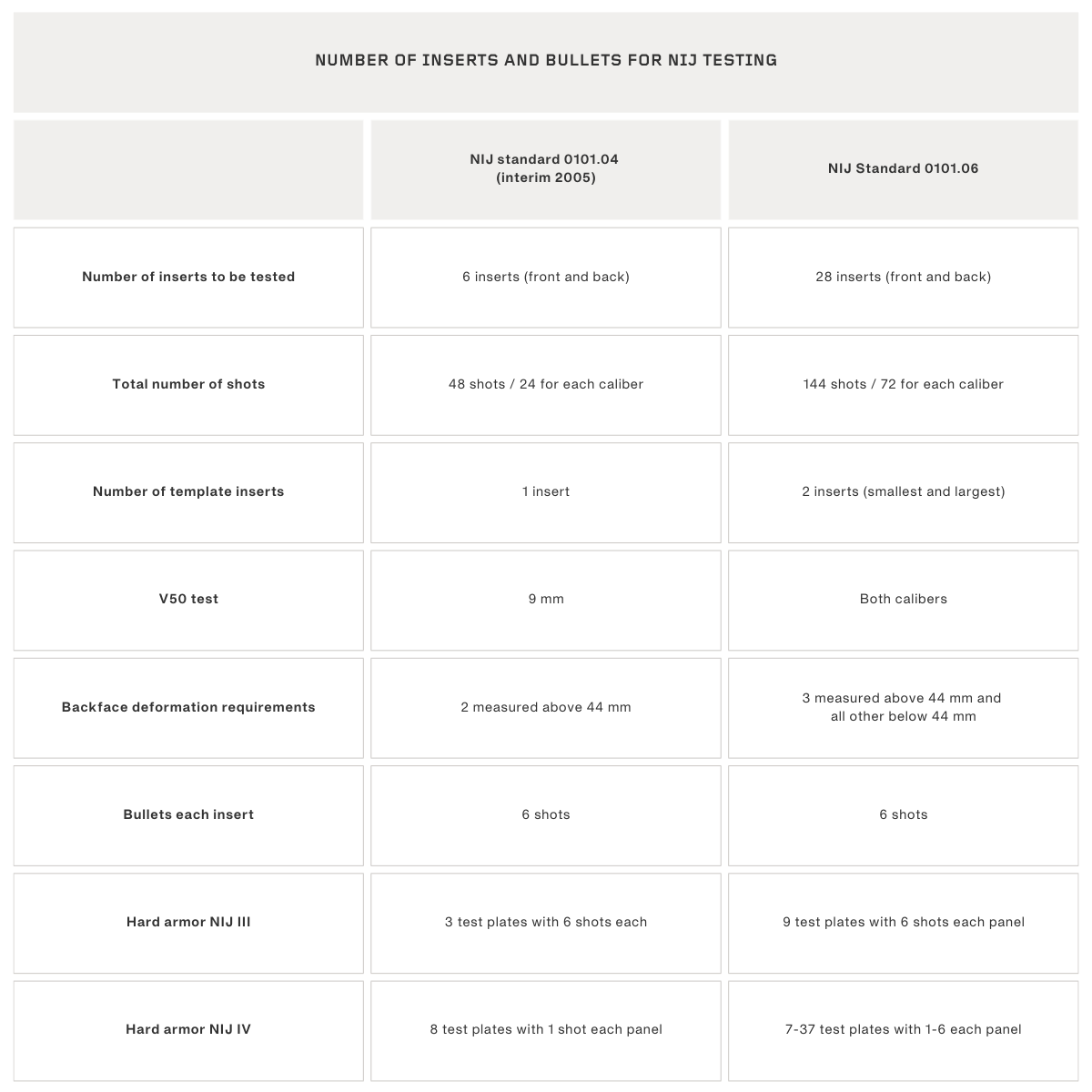

Areas on which NIJ 0101.06 is different than the previous bulletproof standards will be reviewed in the following text:

The above points are essential for your safety. Previously, the shots were spread out on the panel according to NIJ standard 0101.04. For NIJ standard 0101.06, 3th, 4th and 6th shot must be placed in a circle of 3.94 inches. This ensures that the bulletproof vest can withstand multiple bullet impacts in the same area, and still offers a BFS below 44 mm.

Additionally, the “shot to edge” has been modified so that the 9mm FMJ RN and .357 SIG FMJ are placed 2 inches from the edge. This means that bullets close to the edge are required to be stopped.

Under NIJ Standard 0101.04, body armor allowed a shot impact 2 inches from the edge, which could potentially displace the material and cause fatal injury. However, this is not permitted for vests certified under the updated NIJ Standard 0101.06, which enforces stricter requirements to prevent such risks.

The bulletproof inserts that are to be tested according to NIJ standard 0101.06 need to be in the sizes: smallest, small, medium, large and largest.

Typically, the smallest and largest panels are selected for testing, as this impacts the range of models the manufacturer can certify as bulletproof vests. This approach ensures that all vest sizes meet the required standards for certification.

The bulletproof vest also needs to be tested under specific conditions, including dropping into a water bath of approx. 21 degrees for 30 minutes. The former NIJ standard 0101.04 only required a water spray test for 6 minutes, which necessarily didn’t make the body armor waterproof.

Additionally, the test inserts must undergo a tumbling process for 10 days with 72,000 cycles. Before testing ballistic resistance, the inserts are conditioned at a temperature of 65°C with 80% humidity. The ballistic resistance test is then conducted at a slightly lower velocity compared to the standard bulletproof test.

NIJ standard 0101.06 focuses a lot more on safety and everyday use than the former NIJ standard 0101.04. It is always recommended that you check if the bulletproof vest has been tested according to the NIJ 0101.06 standard as this is safer than older NIJ standards.

The NIJ 0101.06 certificate is expensive, but it also ensures the user of a 0101.06 certified bullet proof vest won’t fail. You can read more about NIJ standard 0101.06 here.